Circular Economy: There Is Another Way

The signs of depletion of the planet’s basic resources and the environmental consequences of so much overexploitation are increasingly alarming. The alternative is the circular economy model in which nothing is lost: once used, everything returns to the economic circuit. Some initiatives show that, although much remains to be done, with political and social will it is a possible path.

The consumerist economic model that emerged from industrialization is based on “produce, use and throw away”, without taking into account that we live on a planet with limited resources. In fact, in the last 50 years, our ecological footprint – the surface area of the planet needed to produce everything we use – has increased by almost 190%.

Circular economy: manufacturing without producing waste

The concept of circular economy, on which the EU is committed, breaks this dynamic, so that everything that enters the wheel of production can be used again and again without generating waste (or the minimum possible) or wasting materials premiums, energy or non-renewable resources.

The numbers speak for themselves of the urgency of this change: the EU generates 2,538 million tonnes of waste (4,968 kilos per person, according to Eurostat 2016). Of these, 45.7% end up in landfills and only 37.8% are recycled.

This happens on a planet that shows signs of depletion: the Royal Society of Chemistry of Great Britain, in its document “Endangered elements”, reports on chemical elements that are in danger of extinction, such as neodymium, a mineral that is used in magnets, or tantalum, needed to make touch screens.

Waste becomes valuable raw materials

Recycling is a basic pillar and, with this new vision of the economy, waste becomes a treasure, because, once recycled, it can even have more value than before.

For example, Signus (Integrated Management System for Used Tires) puts a stop to the waste of the 25 million tires that are replaced each year in Spain: it collects the used ones and puts them into circulation as used and retreaded tires, or separates the components (steel, rubber and textile fiber) and are used in the manufacture of cement, asphalt …

For the system change to be possible , the complicity of companies is needed. Therefore, another key concept is that of “industrial symbiosis”. An example is that of Kalundborg (Denmark): for 40 years, public and private companies have collaborated exchanging waste: gas, ash, sludge, organic matter, energy …

Waste leaves one place and enters another to be reused: the ashes of one industry are filtered and used for another to make drywall; the organic residues of some become fertilizer for others. In addition, 3,500 households and a fish farm are heated with excess heat from one of the companies.

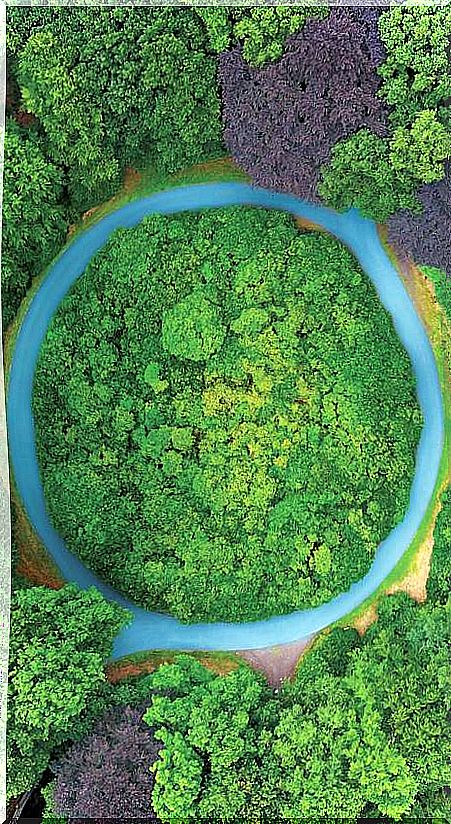

The secret is biomimicry, imitating nature

The circular economy goes beyond recycling and proposes systemic change. The Great Teacher is Nature (biomimicry), where nothing is wasted, everything returns in the form of a nutrient in order to start over and over again.

For the Ellen MacArthur Foundation, one of the main promoters of the transition from the online economy to the circular economy, there are three basic principles:

- Design without generating waste or pollution,

- Ensure that products and materials can be reused over and over again to keep them in the production cycle,

- That allows to regenerate natural systems.

To include plastic in the circular circuit – “nightmare product par excellence” -, the Ellen MacArthur Foundation has promoted the European Plastic Pact, which brings together governments and companies. And duties have been set for 2025:

- Ensure that all single-use plastic packaging and products are reusable whenever possible, and in all cases, recyclable.

- Reduce the need for virgin plastic products and packaging by a minimum of 20%.

- Increase the collection, sorting and recycling capacity of all single-use plastics by 25%.

- Promote the use of recycled plastics (at least 30%) in single-use plastic products and packaging.

The revolution begins with ecodesign

Ecodesign involves “thinking” not only the product, but the entire process of its useful life: 100% recyclable materials and containers are used or that are quickly composted without damaging the natural environment.

For example, Evoware’s food packaging is made from an algae material that dissolves without leaving any residue and can also be eaten.

Another example, the Triodos Bank headquarters in the Netherlands, which has been built with wood and 165,312 screws. All the materials used have been recorded and detailed to the millimeter, in a kind of “materials passport”. If the company needs to relocate or closes, all the components can be disassembled to re-erect the building in another location or to be reused in other constructions, as opposed to a steel and concrete one.

TheCircularLab

The technology applied to recycling and the design of new packaging is another pillar. One sample is TheCircularLab, the Ecoembes innovation center (which manages the recovery and recycling of packaging).

Most of the elements of its headquarters, in Logroño, are second-hand: chairs made from soda cans, buoys turned into lamps …

Its objective is to contribute to the intelligent management of waste (smart waste), the development of the packaging of the future and the strengthening of the business fabric.

They have already promoted 150 projects, including Recycling 5.0, a project so that citizens can “connect” through their mobile with computerized containers and thus count how many times they recycle.

With this you can obtain rewards and exchange them for sustainable incentives. The way forward is starting to look very clear.